agap2 are positioned on 4 poles of intervention that allow us to help our clients in all phases of the projects: both for the fuel cycle and for the power plants.

Discover our areas of expertise.

Studies & Engineering

- Safety studies for the construction, operation and dismantling of nuclear plants,

- Conventional design work (Mechanical engineering, Process, Electricity, Instrumentation, Pipe system, Boilermaking, Civil Engineering, etc.),

- Atomic engineering design work (thermo-hydraulics, criticality, radio-protection, materials, neutronics),

- R&D work and Modelling (CFD, meshing, computing, etc.),

- Technical Inspection of Materials and Equipment.

Project management

- Project management

- Cost control

- Quotes

- Scheduling

- Contract Management / Management of complaints files

Supply Chain Management

- Identification of suppliers.

- Drafting and monitoring of calls for tender.

- Contract management, negotiation.

- Expediting–Supplier Supervision/Reminders.

- Technical inspection of equipment at the supplier’s site/Tracking of manufacturing.

- Management of logistics chain / industrial transport.

Work & Commissioning

- Management of works contracts.

- Supervision / Installation on site.

- Pre-commissioning, Commissioning.

- Testing and validation of equipment.

Dismantling & Management of nuclear waste

- Project management.

- Documentary management.

- SCM.

- Safety studies for the dismantling of nuclear plants.

- Conventional design work (Mechanical engineering, Process, Electricity, Instrumentation, Pipe systems, Boilermaking, Civil Engineering, etc.).

- Atomic engineering studies (thermo-hydraulics, criticality, radio-protection, materials, neutronics).

- R&D work and Modelling (CFD, meshing, computing, etc.).

- Technical inspection / Supervision of manufacturing.

Offshore & Marine studies & engineering

- Basic Engineering / Detailed design work: process, electricity, mechanical engineering, civil engineering, instrumentation, pipe systems, etc.

- Marine and Offshore Studies (drag, seaworthiness, testing in pools, stability, hull structure, keel design, equipment integration.

- Drafting of specifications and data sheets.

- Risk analysis: QRA, risks report, modelling of accident scenarios, impact studies.

- Technical inspection of materials and equipment.

Onshore studies & Engineering

- Basic Engineering / Detailed design work: process, electricity, mechanical engineering, civil engineering, instrumentation, pipe systems, etc.

- R&D work and modelling: design, CFD, computing, etc.

- Drafting of specifications and data sheets.

- Risk analysis: QRA, risks report, modelling of accident scenarios, impact studies.

- Technical inspection of materials and equipment.

Project Management

- Project management

- Cost Control

- Costing

- Scheduling (Macro, Micro, P6 MSP tools, etc.)

- Quality

Supply Chain Management

- Identification of suppliers

- Drafting and issue of calls for tender

- Technical validation of bids

- Management of contracts, negotiation

- Expediting – Supplier reminders

- Technical inspection of equipment on suppliers’ sites

- Management of logistics chain / industrial transport

Construction & Commissioning

- Management of works contracts.

- Supervision / Installation on site.

- Pre-commissioning (Drafting and development of methods, preparation of procedures, etc.).

- Commissioning (Execution, Network connections, Development / Management / Administration of related management systems, Drafting of operating manuals, etc.).

- Testing and validation of equipment.

Engineering

- Basic and detailed design work in all sectors (Mechanical engineering, Process, Electricity HV/LV, Instrumentation, Pipe systems, Boilermaking, Civil Engineering, etc.)

- Electrical Balance Of Plant (E-BOP) studies

- Mechanical engineering Balance Of Plant (M-BOP) studies

- Drafting of specifications and data sheets

- Fluids mechanics

- Technical project management / Coordination of technical interfaces

- Plant and process safety studies

- Maintenance of equipment (revolving machines, electrical stations, etc.)

Supply Chain Management

- Bulk purchasing

- Expediting

- QA/QC inspection

- Transport and logistics

- Project and supplier quality

- Technical inspection of Materials and Equipment

- Audits

Construction & Commissioning

- Supervision on Site

- General installation

- Pre-commissioning, Commissioning for all sectors

- Testing and Validation of equipment

- Field QHSE for power plants

Project Management

- Project management

- Risk management

- Cost Control

- Quotes and costing

- Scheduling

- Contract Management / Claim Management

- Management of documentary control

- QHSE system management

Engineering

- Basic and detailed design work for all sectors (Mechanical engineering, Process, Electricity HV/LV, Instrumentation, Power electronics, Pipe systems, Boilermaking, Civil Engineering, etc.)

- Transmission network connection studies

- Simulation of producibles

- Acoustic studies

- Geographical Information Systems

- Drafting of specifications and data sheets

- Fluids mechanics

- Project technical management / Coordination of technical interfaces

- Maintenance of equipment

Supply Chain Management

- Purchasing (projects or bulk)

- Expediting

- QA/QC inspection

- Transport and logistics

- Quality (projects or suppliers)

- Technical inspection of Materials and Equipment

- Audits

Construction & Commissioning

- Supervision on Site

- General installation

- Pre-commissioning, Commissioning, all sectors

- Testing and Validation of equipment

- Field QHSE

Project Management

- Project management

- Prospection of new sites

- Risk management

- Cost Control

- Quotes and costing

- Scheduling

- Contract Management / Management claims documents

- Management of documentary control

- QHSE management system

Engineering and R&D

- Basic and detailed design work, all sectors (Mechanical engineering, Process, Electricity HV/LV, Instrumentation, Power electronics, Pipe systems, Civil Engineering, etc.)

- Drawings, drafting, technical writing

- Structure design computing

- Project technical management / technical coordination

- Technical inspection of materials and equipment

- Maintenance of equipment (revolving machines, conveyor systems, sifting, crushing, etc.)

Supply Chain Management

- Project purchasing for prime contracting

- Project purchasing for works owner

- CAPEX/OPEX purchasing

- Bulk purchasing

- Expediting

- QA/QC inspection

- Transport and logistics

- Project and supplier quality, etc.)

Construction & Commissioning

- Supervision of erection

- General installation

- Pre-commissioning, Commissioning, all sectors

- Testing and Validation of equipment

Project Management

- Project management

- Risk management

- Cost Control

- Scheduling

- Contract Management / Claim Management

- Management of documentary control

- QHSE

Engineering and R&D

- Basic and detailed design work, all sectors (Mechanical engineering, Process, Electricity HV/LV, Instrumentation, Power electronics, Pipe systems, Boilermaking, Civil Engineering, etc.)

- Process study

- Definition of treatment modes (chemical, bio-chemical, mechanical, membrane filtration, etc.)

- Drafting of specifications and data sheets

- Fluids mechanics

- Project technical management / Coordination of technical interfaces

- Plant and process safety studies

- Maintenance of equipment

Supply Chain Management

- Project purchasing

- Bulk purchasing

- Expediting

- QA/QC inspection

- Transport and logistics

- Project and supplier quality

- Technical inspection of Materials and Equipment

- Audits

Construction & Commissioning

- Supervision on Site

- General installation

- Pre-commissioning, Commissioning, all sectors

- Testing and Validation of equipment

- Field QHSE

Project Management

- Project management

- Risk management

- Cost Control

- Quotes and costing

- Scheduling

- Contract Management / Management of claims documents

- Management of documentary control

- QHSE management system

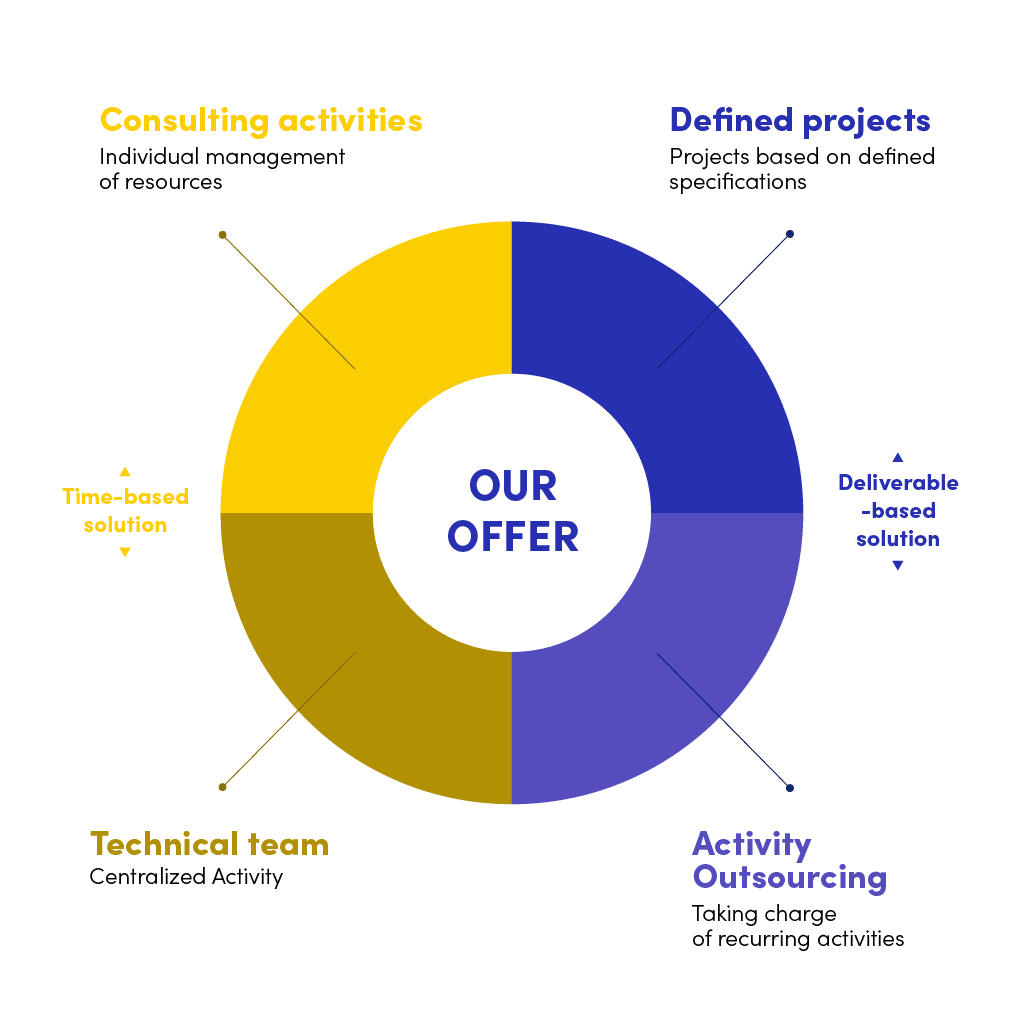

Different levels of commitment.

- Commitment to results.

The commitment to results is adapted to services for which the client wishes agap2 to commit to achieving fixed objectives. It is intended for projects defined in the specifications, for which agap2 proposes a costing per task or project milestone. It allows the search for optimisation and productivity gains and is distinguished by invoicing by deliverables (tasks or milestones).

- Commitment of resources.

The commitment of resources is the most common. It allows great flexibility and responsiveness. It is mainly intended for projects without specifications, with a scope that can change regularly. It is characterised by invoicing for time spent on the project.

Discover our intervention methods.

The aim of our interventions is to respond to our clients’ problems in the most accurate and appropriate way possible. To do this, we have built our offer on 4 modes of intervention with increasing levels of commitment.

- Consulting activity: Individual resource management | Contract for each consultant | Responsiveness and flexibility | Commitment of means

- Defined projects: Projects based on defined specifications | Project management by Projects Solutions | Implementation of a multidisciplinary team | Commitment to results

- Technical platform: Centralised activity | Delegation of management Single contract | Management of skills and resources by Projects Solutions | Commitment of means

- Outsourcing: Management of recurrent activities | Division of activities into tasks or work packages | Management of the workload by Solutions Projects | Commitment to results